Process for Synthesis of Poly-Acrylamide-Hydroxamate (PAH) Resin for Recovery of Selective Metal Ions

Poly-Acrylamide-Hydroxamate (PAH) is aliphatic, three dimensionally cross-linked, peach colored, irregularly shaped, highly hydrophilic weak amphoteric chromatographic resin for transition metal sequestration/chelation e.g. copper, lead, nickel, arsenic, mercury, cobalt, cadmium, molybdenum, lanthanides recovery, generated from chemical, pharmaceutical, electroplating, leather industries.

PAH is easy to synthesize, no heavy infrastructure is required, (once the reaction starts) can be left without constant monitoring and all ingredients are easily available in local market, inexpensive, water soluble and hence synthesis in aqueous (sole solvent) medium is least toxic, hazardous and with almost no volatile organic content(VOC).

PAH resin is synthesized in aqueous medium (no organic solvent) only, extremely efficient in extracting multivalent transition metal even from ppb level, reducing chemical and radio-toxicity with efficient VRF and DF helps in reducing waste inventory, risk, monitoring time and cost of managing industrial waste.

Poly-Acrylamide-Hydroxamate (PAH) is synthesized in aqueous medium (no organic solvent) only, a hydrophilic weak amphoteric chromatographic sequestration/chelation resin for copper, lead, nickel, arsenic, mercury, cobalt, molybdenum, manganese, vanadium, cadmium, lanthanides recovery. Variation in sorption kinetics and leaching of metal/s laden PAH by fractional elution are advantageous for metal ion/s as well as resin recovery with high volume reduction factor (VRF-10-100) for effluents' and metal or chemical useful for chemical, pharmaceutical, electroplating, leather industries.

- Specialized structured aliphatic back-bone, pendant functional moieties, high capacity, reusable resin.

- PAH resin ensuring polishing with true chromatography during column operation.

- High metal decontamination, immobilization efficiency and volume reduction factor.

- Chromatogram/metal chelate color PAH minimizes analytical instruments application.

- Although completely incinerable, cementation is the easiest waste treatment process.

- Synthesis, Purification, and column methodology established.

- Non-DAE and DAE related application for industrial effluent treatment.

- PAH is a chromatographic resin for Spot test where analytical facilities are inaccessible.

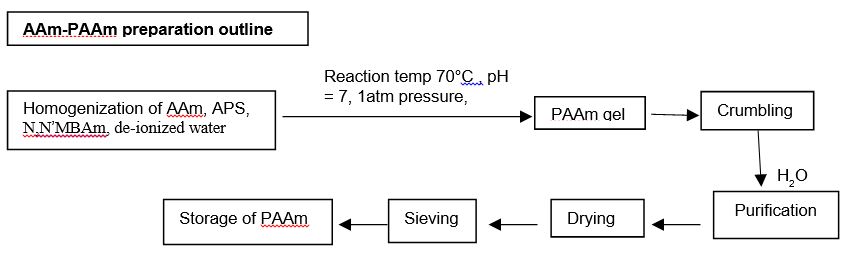

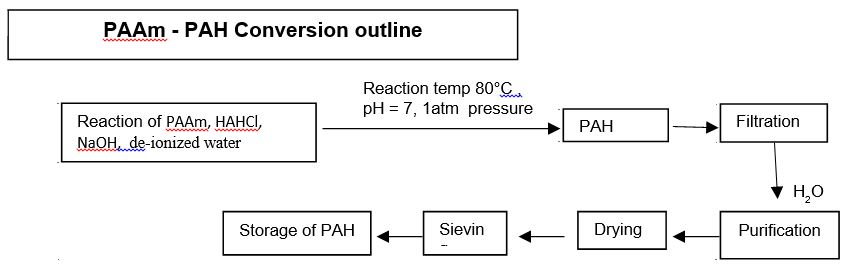

Poly-Acrylamide-Hydroxamate (PAH) resin synthesis is a two-steps process; i. Polyacrylamide(PAAm) preparation, ii. Functionalization/conversion of PAAm to PAH resin. Water is the sole solvent and ingredients are water soluble. The PAH resin is useful for copper, lead, nickel, arsenic, mercury, cobalt, cadmium, lanthanides recovery, for effluents generated from chemical, pharmaceutical, electroplating, leather industries.

PAH resin has been useful in the treatment of chemical industry such as electro-deposition with expensive lanthanides recovery from effluent, laboratory effluent treatment for valuables recovery.

PAH resin is already established its features in one effluent treatment plant with three-stage-industrial effluent treatment processes and will be incorporated into future management facilities as well. As such, PAH resin will remain as an important component for effluent treatment in India in the years to come. Hence, its production and availability at a competitive price on commercial scale is of paramount importance. PAH is a solid resin with a required purity combination of 40% acrylamide and 60% hydroxamate sequestering group with cumulative structural efficacy of 98% attributed to its architectural and recurrence symmetry for efficient process operation.

- Non-DAE and DAE related application for industrial effluent treatment for transition metal ions.

- High sorption efficiency, selectivity, selective fractional elution, kinetics and reusability for instant absorption, spillage removal and decontamination.

- PAH is a chromatographic resin useful for Spot test even in remote areas where analytical facilities are inaccessible.

- Special aliphatic functionalized, high capacity reusable resin for industrial effluent treatment.

- Supporting and ensuring chromatographic polishing resin in industrial effluent treatment operation.

- High decontamination and immobilization efficiency with substantial volume reduction factor.

- Chromatogram minimizes application of analytical instruments.

- Although completely incinerable, cementisation is the easiest and efficient "waste treatment" process or else pyrolysis to destroy "resin-organic back bone structure" is another added process of "after-use PAH resin treatment with metal recovery.

- Easy Eco-Synthesis with atmospheric pressure, temperature (80°C), common infrastructure facility, basic trained common manpower required.

- Synthesis, Purification, and Quality Control Procedures established.

Facilities required

- Chemical Manufacturing & Research experienced unit.

- Essential equipped manufacturing facility (ISO Certified, if possible).

- Reactors in Glass and non-corrosive, preferably non-metallic vessel.

- Glass and non-corrosive, preferably non-metallic equipments and cloths for purification.

- One filtration unit and drying unit equipped with sieving instrument before packing.

- Complying with safety and environmental regulations.

- Raw material is easily available in local market.

- One chemist (BSc) or one skilled worker are required.

| SR NO. | COUNTRY NAME | PATENT NUMBER | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| No Data Found. | |||||||||||||

| SR NO. | NAME | STANDARD NUMBER | LOGO | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| No Data Found. | |||||||||||||

General License Fee : ₹ 127,500.00 (One Lakh Twenty Seven Thousand Five Hundred)

General Royalty : 0%