Chlorine Dioxide releasing polymer for water disinfection (CLEAN)

BARC developed technology “ChLorine dioxidE releAsiNg polymer (CLEAN)”

which has eliminated the biggest constraint of in situ generation of

chlorine dioxide. CLEAN is biodegradable polymer based chlorine dioxide

releasing polymer which can be used for “on demand” water disinfection.

The polymer can be synthesized for predetermined dose and dose rate of

chlorine dioxide by altering its constituents. Being completely

biodegradable, it does not create any environmental pollution. Chlorine

dioxide (ClO2) is a very effective biocide for drinking water

disinfection and biofouling control. The CLEAN polymer composite can be

used for water disinfection of various volume and easily scalable. It

can be used to preserve water for longer duration (water storage tank,

overhead tanks, water transportation etc) as well as for shorter

duration.Similarly this can also be used as “on the go” water purifier

where one can get water purified (pathogen free) in less than 15

minutes.

BARC developed technology “ChLorine dioxidE releAsiNg polymer (CLEAN)”

which has eliminated the biggest constraint of in situ generation of

chlorine dioxide. CLEAN is biodegradable polymer based chlorine dioxide

releasing polymer which can be used for “on demand” water disinfection.

CLEAN can be synthesized for predetermined dose and dose rate of

chlorine dioxide by altering its constituents. Being completely

biodegradable, it does not create any environmental pollution. Chlorine

dioxide (ClO2) is a very effective biocide for drinking water

disinfection and biofouling control. It is an EPA and FDA approved

biocide, which under proper generation conditions, unlike chlorine, does

not produce halogen-substituted by-products called Trihalomethane

(THMs) which are known carcinogens. It is more effective than chlorine

and chloramines for inactivation of all types of microorganisms such as

bacteria, viruses, fungi and protozoans, including Cryptosporidium and

Giardia. However, unlike chlorine, it needs to be generated in situ as

it cannot be stored or transported.

ADVANTAGES

-

There are few distinct advantage of chlorine dioxide over other biocides such as;

It remains in dissolve gas form and therefore it has better penetration and thus has effective killing. The disinfection efficiency of chlorine dioxide is not influenced by pH and organics present in water. The disinfection process does not lead to generation of THM or DBP’s. -

The control over release rate of chlorine dioxide makes this polymer a unique formulation which can be used for water disinfection application having variable time period (i.e., disinfection in 15 mins to a sustained release up to 15 days).

-

The polymer is biodegradable and upon degradation converted into fatty acid which can be easily metabolized by human.

APPLICATIONS

-

The CLEAN polymer composite can be used for water disinfection under various conditions.

-

It can be used to preserve water for longer duration (water storage tank, overhead tanks, water transportation etc).

-

Similarly this can also be used as “on the go water” purifier where one can get water purified (pathogen free) in less than 15 minutes.

Chlorine dioxide (ClO2) is a very effective biocide for drinking water disinfection and biofouling control. It is an EPA and FDA approved biocide, which under proper generation conditions, unlike chlorine, does not produce halogen-substituted by-products called Trihalomethane (THMs) which are known carcinogens. It is more effective than chlorine and chloramines for inactivation of all types of microorganisms such as bacteria, viruses, fungi and protozoans, including Cryptosporidium and Giardia. However, unlike chlorine, it needs to be generated in situ as it cannot be stored or transported.

BARC developed technology “ChLorine dioxidE releAsiNg polymer (CLEAN)” which has eliminated the biggest constraint of in situ genration of chlorine dioxide. CLEAN is biodegradable polymer based chlorine dioxide releasing polymer which can be used for “on demand” water disinfection. CLEAN can be synthesized for predetermined dose and dose rate of chlorine dioxide by altering its constituents. Being completely biodegradable, it does not create any environmental pollution.

ADVANTAGES

- CLEAN polymer utilizes the potent antimicrobial property of chlorine dioxide without limitation of requirement of its resource intensive on site generation.

- There are few distinct advantage of chlorine dioxide over other biocides such as;

- it remains in dissolve gas form and therefore it has better penetration and thus has effective killing ( including biofilm).

- The disinfection efficiency of chlorine dioxide is not influenced by pH and organics present in water.

- The disinfection process does not lead to generation of THM or DBP’s.

- The control over release rate of chlorine dioxide makes this polymer a unique formulation which can be used for water disinfection application having variable time period (i.e., disinfection in 15 mins to a sustained release up to 15 days).

- The polymer is biodegradable and upon degradation converted into fatty acid which can be easily metabolized by human.

APPLICATIONS

- The CLEAN polymer composite can be used for water disinfection under various conditions.

- It can be used to preserve water for longer duration (water storage tank, overhead tanks, water transportation etc).

- Similarly this can also be used as “on the go water” purifier where one can get water purified (pathogen free) in less than 15 minutes.

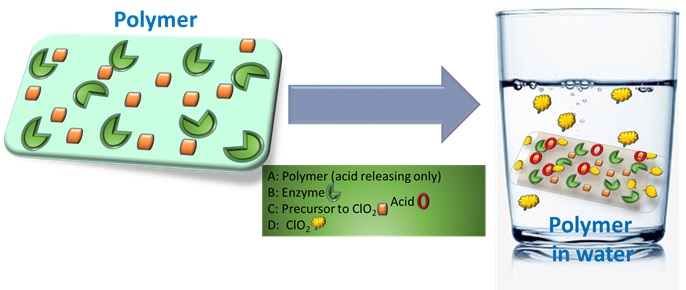

WORKING PRINCIPLE

When CLEAN polymer comes in to contact with water, the enzyme

embedded inside will start hydrolytic reaction resulting in the

generation of acid in microenvironment. This acid reacts with sodium

chlorite present in its vicinity and converts it in to chlorine dioxide.

This chlorine dioxide is released in to water and kills the

microorganisms.

RAW MATERIALS

-

Industrial grade raw materials required for CLEAN manufacturing

are easily available in local market and can be purchased at bulk rate.

INFRASTRUCTURE

- A chemical laboratory having fume hood, industrial lyophilizer and basic microbiological analysis facility is required for manufacturing of CLEAN.

MANPOWER

One trained person having

degree in Chemistry and one person having degree in Microbiology with

two semi-skilled workers would be adequate for production of Chlorine

dioxide releasing polymer unit.

| SR NO. | Organization name | Licensee Name | Licensee Code | ACQUIRED ON | Valid Till | Address | City | State | Phone | |

|---|---|---|---|---|---|---|---|---|---|---|

| 01 | M/s Shrinathji Kayakalp Remedies Pvt. Ltd., | Shri Pawan Maheshwari, Director | 90 | 06-01-2022 | 05-01-2027 | 98-Sector A, Industrial Area, Mandideep | Raisen | Madhya Pradesh | skr_remedies@rediffmail.com | |

| 02 | DEVANSHI WATER | MRS.JYOTI KUMAR ANEJA | 560 | 23-08-2022 | 22-08-2027 | DEVANSHI WATER, FLAT NO:2101, UNITECH FRESCO TOWER-2 NIRVANA COUNTRY GURGAON HARYANA PIN - 122018 | Gurgaon | Haryana | aneja.pranav@gmail.com | 9711117081 |

| 03 | GLOBAL BIOSCIENCES | RAJESH SETHIA | 514 | 25-07-2022 | 24-07-2027 | PLOT NO-2, STREET NO-10, SECTOR-A, BORSI, DURG-491001 | Durg | Chhattisgarh | globalbio_788@rediffmail.com | 9406020248 |

| 04 | M/s Cleanflo India Pvt. Ltd | Shri Shikhar Sharma | 148 | 24-02-2021 | 23-02-2028 | M/s Cleanflo India Pvt. Ltd., 403, Gupta Tower, Commercial Complex, Ring Road | Azadpur | Delhi | shikhar@cleanfloindia.com | 01147003700 |

| 05 | HIDDEN ELEMENTS PVT. LTD. | Mr. Rahul Maheshwari | 569 | 24-06-2022 | 23-06-2027 | HIDDEN ELEMENTS PVT. LTD., 119, SECTOR-E, ARERA COLONY, BHOPAL PIN: 462039 (M P) | Bhopal | Madhya Pradesh | support@hidenelements.com | 9245149149 / 99 |

| 06 | HES Water Engineers India Pvt. Ltd. | Narender Ahuja | 551 | 27-04-2023 | 26-04-2028 | K27, Five Star Industrial Zone, MIDC, Butibori | Nagpur | Maharashtra | nahuja@hesweindia.com | 9822126166 |

| 07 | TAYLORMADE RENEWABLES LIMITED | Mr. Dharmendra Gor | 689 | 06-02-2024 | 05-02-2029 | 705, SHAPATH -II, OPP. RAJPATH CLUB, S. G. ROAD, BODAKDEV, | Ahmedabad | Gujarat | dharam@tss-india.com | 09712933390 |

| SR NO. | COUNTRY NAME | PATENT NUMBER | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| No Data Found. | |||||||||||||

| SR NO. | NAME | STANDARD NUMBER | LOGO | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| No Data Found. | |||||||||||||

General License Fee : ₹ 110,000.00 (One Lakh Ten Thousand)

General Royalty : 0%