Atmospheric pressure portable catalytic air plasma system for fast synthesis of aqueous Nitrate & Nitrite fertilizers

Fig 1

Nitrate and nitrites are essential nutrients for the crops. The present invention offers a portable thermal plasma device for fast synthesis of nitrate and nitrite in high concentration, via a catalyst based green process leaving zero carbon footprints. A highly reactive thermal plasma environment facilitates the synthesis process at a power level of 20 kW at atmospheric pressure does not use any additional chemical, and directly converts atmospheric air into nitrate and nitrite through interaction with water in a very efficient and controlled manner. This system offers a clean, sustainable, decentralized, flexible alternative method for generation of nitrates and nitrites that may be used as nitrogen based crop fertilizer. Achieved concentration is several orders of magnitude higher than that achievable in competing non thermal plasma processes.

1 Fig 1

Nitrates and nitrites are essential nutrients of life. The present invention offers a portable thermal plasma device for fast synthesis of nitrate and nitrite fertilizer in high concentration, via a catalyst based green process leaving zero carbon footprint. A highly reactive thermal plasma environment facilitates the synthesis process at a power level of 20 kW at atmospheric pressure. The process does not use any additional chemical, and directly converts atmospheric air into nitrate and nitrite through interaction with water in a very efficient and controlled manner. The system offers a clean, sustainable, decentralized, flexible alternative for synthesis of nitrates and nitrites that may be used as nitrogen-based crop fertilizer. Achieved synthesis rate is several orders of magnitude higher than that achievable in competing non thermal plasma processes.

1 Fig 1

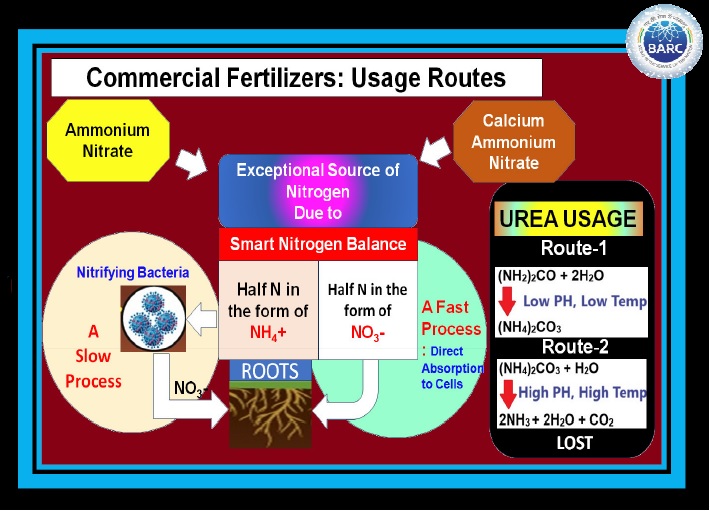

Nitrates and nitrites are essential nutrients of life. Although our atmosphere is full of nitrogen, plants cannot directly consume it. It needs to be converted into the form of nitrate or nitrite, which plants can assimilate. Lightning is a natural process, which does this job, but not as a controlled event under optimized condition for an efficient synthesis.

The present invention adopts a highly reactive thermal plasma process similar to natural lightning and offers a portable thermal plasma device for fast synthesis of nitrate and nitrite in high concentration, via a catalyst based green process with zero carbon footprints.

Competing technology like Haber-Bosch process requires high pressure (~ 300 bars), accounts for 1% of global annual CO emissions, and generates 1.9 tons of CO per ton of ammonia [P. H. Pfromm, J. Renewable Sustainable Energy 2017, 9, 034702;Y. Gorbanev et.al., ACS Sustainable Chem. Eng. 2020, 8, 2996].

Invented low power (~10-20kW) thermal plasma catalyst based technology works at atmospheric pressure, does not use any additional chemical, and directly converts atmospheric air into nitrate and nitrite through interaction with water in a very efficient and controlled manner. This is equivalent to continuous lightning process under optimized environment giving synthesis rate several orders of magnitude higher than that achievable in competing non-thermal plasma processes.

The system offers a clean, sustainable, easily decentralizable, flexible alternative for generation of nitrates and nitrites that may be used as nitrogen based crop fertilizer.

- The present invention relates to a revolutionary atmospheric pressure portable catalytic air plasma system, designed for the rapid synthesis of aqueous NO2ŌłÆ and NO3ŌłÆ fertilizer directly from abundant natural resources such as air and water.

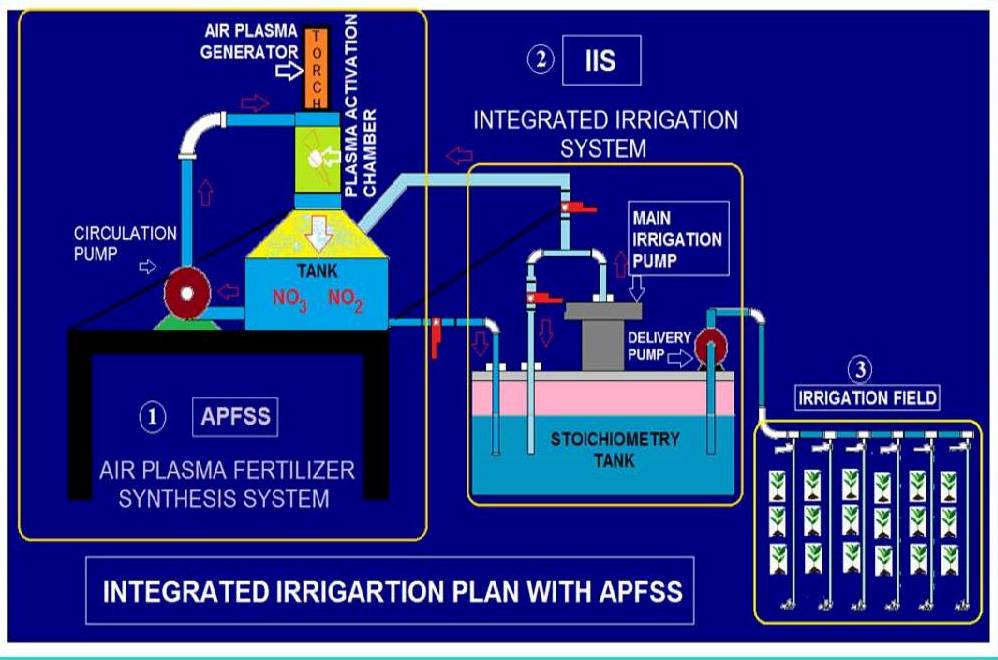

- The system comprises of an air plasma torch featuring a hafnium electrode, operating within a power range of 15-25 kW, coupled with a catalytic bed and mist generator enclosed within a plasma interaction chamber. Water distribution mechanisms facilitate mist generation surrounding the plasma torch exit, promoting efficient interaction with plasma constituents.

- The catalytic bed, housing a specially designed catalyst cartridge composed of transition metals, enables synthesis rates exceeding 1600 mg/min in a single-step process. The innovative design ensures atmospheric pressure operation, portability, and compatibility with intermittent renewable energy sources. Notably, the synthesized fertilizer is directly consumable, minimizing environmental pollution and eliminating greenhouse gas emissions. The system's decentralizable nature allows for on-site installation close to agricultural fields, reducing transportation and distribution costs.

- Overall, this invention represents a significant advancement in fertilizer synthesis technology, offering unparalleled synthesis rate, sustainability, and environmental benefits.

- A catalyst based portable thermal plasma device that offers an environment friendly economic green route for synthesis of nitrogen based fertilizer at a synthesis rate greater than 1500 mg/min.

- A water based nitrogen fertilizer system that can directly be part of the irrigation network and deliver fertilizer to the field via existing irrigation provision.

- A catalyst based highly reactive thermal plasma reactor, capable of producing nitrate and nitrite fertilizer in high concentration directly from atmospheric air and water.

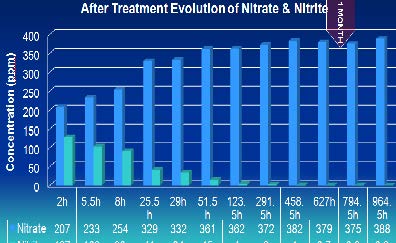

- A catalytic thermal plasma device that synthesizes water based nitrogen fertilizer, preserving its concentration for more than a month.

- A catalytic thermal plasma device that meets onsite nitrogen demand of crops in requisite amount, as and when required, avoiding safety hazards and costs related to requirement of continuous energy resources, pressurized environment for synthesis, regulated storage, refrigeration need, transport of raw materials and distribution of fertilizer.

- A thermal plasma based catalytic system for synthesis of nitrogen based fertilizer that

- completely avoids production of green house gases like CO2

- avoids production of harmful intermediates like ammonia

- leaves zero carbon foot print in synthesis of nitrogen based fertilizer, when operated with renewable energy

- produces mix of nitrates and nitrites for a prolonged supply of nitrate via gradual and automatic conversion of nitrite into nitrate over a period of time

- The invention involves a system consisting of an air plasma torch at the top of the setup followed by a down-stream catalytic reaction chamber embedded in a water shower manifold, a water collection tank, and a water circulation system with adjustable flow and delivery pressure.

- The torch operates at atmospheric pressure and generates a thermal plasma jet of air with core temperature around 8000K.

- A net shaped cylindrical catalyst bed is mounted completely occupying the radial extent of the holding chamber with a special positioning provision. It stays immerged in the mixed liquid vapour phase of water while receiving heat from the plasma jet and maintaining its temperature within 45-50┬░C.

- Functioning of the air plasma torch involves an air compressor capable of delivering air-flow of 30 slpm at a pressure of 4 kg/cm2, a constant current power supply with open circuit voltage of 400V and maximum current delivery capacity of 200A and a chilled water supply unit of capacity 2 Tr to cool the thermally stressed components. Highly reactive species are contributed by the plasma torch in the atmospheric pressure air plasma generated

- Unlike multistep conventional processes involving extensive instrumentation, this is a single step thermal plasma process directly producing nitrate and nitrite fertilizer from air and water.

- Fertiliser is synthesized in the form of nitrate and nitrite ions. Both of them can be directly assimilated by plants.

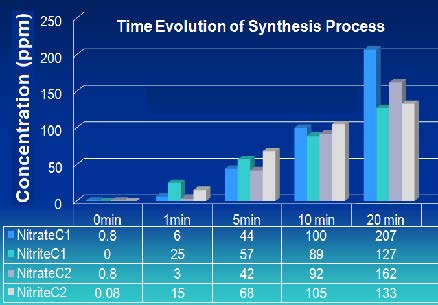

- While the typical duration of synthesis is only 20 minutes, the concentration of nitrate and that of nitrite continues to evolve even after synthesis.

- After synthesis net concentration of nitrogen fertilizer (nitrate + nitrite) in the treated water remain nearly constant with time.

- It has been observed in the synthesis process that use of catalyst almost doubles the nitrate concentration and increases the nitrite Novelty concentration four fold in 20 minutes compared to the same obtained without use of catalyst.

- Initially, at least up to first five minutes nitrite is synthesized at a rate faster than that of nitrate and then the synthesis rate of nitrite and nitrate reverses.

- Observed average synthesis rate of nitrate in the invented thermal air plasma process is around 26000 times higher than that commonly realized in non thermal plasma process.

- The same for nitrite is around 85000 times higher in the invented process.

- This is a completely green process with zero carbon foot print, when operated with renewable energy.

- Actual usage of Urea (Nitrogen Fertilizer) depends on PH of soil and soil temperature. Need activity of nitrifying bacteria. Major part may be lost to environment as ammonia if PH and temperature are not proper.

- BARC invented technology directly synthesizes stable nitrate, the final product directly consumable by plant. No loss to environment is involved.

PATENT INFORMATION

| DAE Patent # | 437320 |

| Date of filing | 11/04/2017 |

| Patent Title | Air Plasma Torch |

| Inventor | Dr. Srikumar Ghorui, L&PTD, BARC |

| DAE Patent: Appl.# | 202421017733, 12th March 2024 |

| Patent Title | Atmospheric Pressure Portable Catalytic Air Plasma System for Synthesis of Aqueous NO2 and NO3 Fertilizer |

| Date of filing | 12/03/2024 |

| Inventor | Dr. Srikumar Ghorui, L&PTD, BARC |

| SR NO. | Organization name | Licensee Name | Licensee Code | ACQUIRED ON | Valid Till | Address | City | State | Phone | |

|---|---|---|---|---|---|---|---|---|---|---|

| 01 | United BioEnergy Pvt Ltd | Atul Nalawade | 904 | 22-11-2024 | - | 1701/A, Sai Tirth Tower, Siddharth Nagar, Kopri Thane East | Thane | Maharashtra | atul@unitedbioenergy.co.in | 7666718455 |

| 02 | NANO FERTILIZERS PRIVATE LIMITED | Arjun Agarwal | 926 | 23-10-2024 | 22-10-2029 | 304, 3RD FLOOR ROOTS TOWER, LAXMI NAGAR DISTT. CENTRE , DELHI, Delhi, India - 110092. | Delhi | Delhi | arjun@nano-fertilizers.com | 9721900000 |

| 03 | GROW CONTROL | G Ramdevi R | 927 | 22-11-2024 | 21-11-2029 | P-5/1/A, Road No.13, Industrial Development Area, Nacharam, Hyderabad, Telangana 500076 | Hyderabad | Telangana | info@growcontrol.in | 040 2717 5591 |

| SR NO. | COUNTRY NAME | PATENT NUMBER | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| No Data Found. | |||||||||||||

| SR NO. | NAME | STANDARD NUMBER | LOGO | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| No Data Found. | |||||||||||||

General License Fee : ₹ 250,000.00 (Two Lakh Fifty Thousand)

General Royalty : 0%